The transportation modes of lithium batteries include air transportation, water transportation, and land transportation. So far, the most commonly used air transportation and sea transportation are mainly discussed.

Because lithium is a metal that is particularly prone to chemical reactions, stretching and burning, lithium battery packaging, and transportation, such as improper handling, easy to burn, and explosion, accidents also occur from time to time. More and more attention has been paid to accidents caused by non-standard behaviors in packaging and transportation. A number of international organizations have issued a number of regulations, and various management organizations have become increasingly strict, raising operational requirements and constantly revising regulations and regulations (for example, IATA has revised regulations for lithium battery transportation every two years).

Are you planning on shipping your lithium batteries or your IoT devices by air, sea, rail, or road? You may not realize it but there are a number of rules that must be adhered to. Lithium batteries are classed as dangerous goods in transportation. With billions of non-rechargeable and rechargeable lithium cells and batteries powering most of the world’s consumer and industrial electronic devices, shipping them to the customer through vast global logistics chains is often an overlooked subject.

Safety requirements have led to a tightening of air transport regulations when transporting lithium batteries. Failing to follow these rules could lead to serious consequences, including significant fines. With that in mind, it’s essential for you – and your chosen carrier – to take the time to ensure that during shipping, these lithium batteries are appropriately declared, labeled, packaged, and stored.

So, what do you need to know before shipping lithium batteries or battery-powered IoT devices?

1. Find a shipping company that can transport lithium batteries

First and foremost, when shipping lithium batteries by road, sea, rail, or air, you should choose a reputable carrier that has guidelines in place for shipping these items, together with trained personnel who understand how lithium batteries work and how to handle them safely. FedEx, USPS, UPS, or DHL can do the job but there are other commercial carriers. Just make sure they have a hazmat contract or a pre-approval for your specific type of lithium batteries and follow the UN/IATA/ICAO/ Dangerous Goods regulations.

Since 2016, the transport of lithium-ion batteries aboard passenger aircraft in bulk shipments have been prohibited so you’ll have to find the relevant carrier. This prohibition is not applicable to batteries packed with or contained in equipment. Note: There are specific cargo-only carrying aircraft following the ICAO regulations, which allow lithium cells and batteries to shipped in bulk.

Packing and labeling is the responsibility of the shipper. You will be required to provide the carrier with the appropriate documentation. Most of these companies will provide you with a Shipping Guide stating their specific requirements for lithium-ion and lithium metal battery shipments according to the chosen mode of transport. Don’t forget, most freight nowadays is multi-modal: the shipment could start its journey by road, followed by air and then by road or rail. Packing your shipment for air transport is the surest way to ensure it will comply with the necessary requirements all the way.

2. The classifications and shipping descriptions

All hazardous materials are subject to the UN regulations and are assigned one of nine hazard classes. Lithium batteries have been assigned to Class 9- Miscellaneous Hazard Classification.

Additionally, the United Nations Committee of Experts on the Transport of Dangerous Goods has classified dangerous goods under specific UN Numbers and “proper shipping names”. There are six possible shipping names (and labels) with corresponding UN numbers for lithium battery shipments based upon the type and how the package is configured:

- UN 3480 Lithium-ion batteries (rechargeable)

- UN 3481 Lithium-ion batteries contained in equipment

- UN 3481 Lithium-ion batteries packed with equipment

- UN 3090 Lithium metal batteries (non-rechargeable lithium batteries)

- UN 3091 Lithium metal batteries contained in equipment

- UN 3091 Lithium metal batteries packed with equipment

You will need to indicate the sizing of the batteries on your battery product label. Lithium-ion batteries are sized by power rating in Watt-hours (Wh) per cell and Watt-hours per battery. Normally, the power is indicated on the battery itself, as this is now mandatory (older batteries manufactured before 1st January 2009 may lack this labeling). Make sure you confirm the information with your manufacturer as it might not be indicated on the cell. For GREPOW batteries, the information is indicated in the datasheet available for each one of our batteries.

3. Prove your credentials: The UN 38.3 test summary

As of 1st of January 2020, producers and subsequent distributors of cells or batteries must make available a Test Summary Report or TSR—as specified in the UN Manual of Tests and Criteria— before lithium cells/batteries can be transported. This is a series of 8 tests simulating safety in transport and environmental transport conditions such as pressure, temperature, shock, vibration, impact, altitude, etc. The test summary report includes a summary of the cell or batteries’ test results. Without this test summary report being made available to the transport logistics chain, the shipping of lithium cells and batteries is prohibited.

At GREPOW we do all of our own testings and provide the UN 38.3 test summary report online. Simply provide the full part number (P/N) to obtain the corresponding test report.

Be warned, when choosing your battery manufacturer, only cells and batteries manufactured under a quality management program may be offered for transport.

4. Pack your lithium batteries shipment

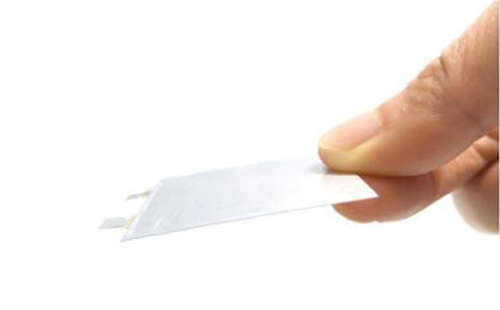

The packing is usually handled by the entity that ships the package as they are typically the signatories on the shipping declaration, which requires specific information depending on a number of parameters. The detailed requirements for any given lithium battery shipment may vary significantly depending on the battery type, size, quantity, configuration, weight, transporter, destination, and mode of transportation. It also depends on whether you are shipping batteries or cells only, cells or batteries packed with equipment (separately in the same package) or cells or batteries contained in equipment. The “Recommendations on the Transport of Dangerous Goods Model Regulations, Twenty-first revised edition (ST/SG/AC.10/1/Rev.21)” is the base reference document underlying the regulatory structure for all transport modes. This document is publicly available at the link in the glossary below.

The document provides detailed guidance for classification, packaging and many other details, specific to various cases of transport for all classifications of dangerous goods including Lithium rechargeable and non-rechargeable cells and batteries – for example;

- Small quantities of Li metal and Li-ion cells and batteries.

a. Special provision, Chapter 3.3, 188 (a), (b) etc. - Lithium cells and batteries when installed in equipment.

a. Special Provision Chapter 3.3, 188 (e), etc.

Packaging instructions specific to the various transport modes can be found on the respective websites of the institutions and organizations listed in the glossary at the end of this post. Depending on the product you are shipping, where you are shipping and how, the shipper will have to follow the applicable packing requirements of the current edition of the United Nations Recommendations on the Transport Of Dangerous Goods Model Regulations and the requirements of other regulatory bodies (ICAO, IATA, IMDG, ADR, DOT, RID) depending on the intended mode of transport; a road, rail, air, sea or multi-modal.

Care must be taken to understand any additional requirements imposed by the different modes of transport. Additional requirements and restrictions may be imposed by the various carriers, many of which address Lithium battery shipments.

Packaging may require official testing to prove it will protect its contents during transport when exposed to dropping, stacking, moisture, etc, before being allowed to transport Lithium cells and batteries. Fortunately, this type of qualified packaging is readily available and pre-qualified from suppliers globally.

Nowadays, billions of batteries are shipped annually. Lithium battery accidents in transport are very rare, thanks to the regulations and high standards for air, road, sea, and rail shipping. At first glance, it may appear a daunting task, but on the contrary, it is not difficult to ship your batteries or battery-powered devices, you just need to know what you are doing before you start! And you need to make sure that your chosen carrier is up to date with the regulations and follows the revisions that are being published on a regular basis.

If you need any advice on how to transport your GREPOW batteries for the Internet of Things, please get in touch with GREPOW at info@grepow.com where your inquiry will be directed to a knowledgeable specialist, who can set you on the path to safely preparing your shipments in compliance with international transport regulations.

Glossary

- IATA International Air Transport Association.

- ICAO International Civil Aviation Organization.

- DOT U.S. Department Of Transport.

- UN United Nations.

- FAA Federal Aviation Administration

- IMDG International Maritime Dangerous Goods

- RID Regulation concerning the International Carriage of Dangerous Goods by Rail

- ADN International Carriage of Dangerous Goods by Inland Waterways

- ADR European Agreement – International Carriage of Dangerous Goods by Road

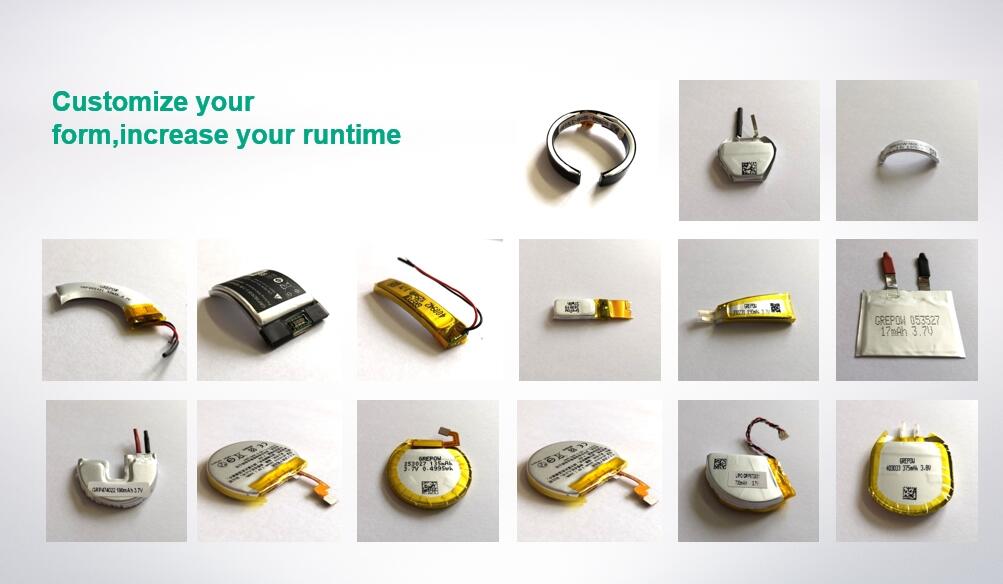

Shenzhen Grepow Battery Co., Ltd. was founded in 1998. We are an advanced technology company specialized in the research and production of rechargeable button-cell battery, NIMH, Li-po batteries(made into any shaped battery), LiFePO4 batteries, and the development of power management systems. After decades of development, Grepow is now one of the largest manufacturers of high C-rate and high capacity batteries in China. Our self-owned brands “格氏ACE”, “GENS ACE” and “TATTU” are renowned home and abroad.

If you are interested in our battery products, please don’t hesitate to contact us at any time!

Email: info@grepow.com

Grepow Website: https://www.grepow.com/

IoT batteries: https://www.grepow.com/page/iot-battery.html

Low-temperature lithium-ion battery, including low-temperature 18650 lithium-ion battery, low-temperature pouch polymer lithium-ion battery, and a low-temperature iron phosphate lithium-ion battery. Batteries these kinds, each

Low-temperature lithium-ion battery, including low-temperature 18650 lithium-ion battery, low-temperature pouch polymer lithium-ion battery, and a low-temperature iron phosphate lithium-ion battery. Batteries these kinds, each